New product | JBMACH Launohs Type HRJ Pwsher Centrifuge

Category: JBMACH News

Time: 2021-07-23

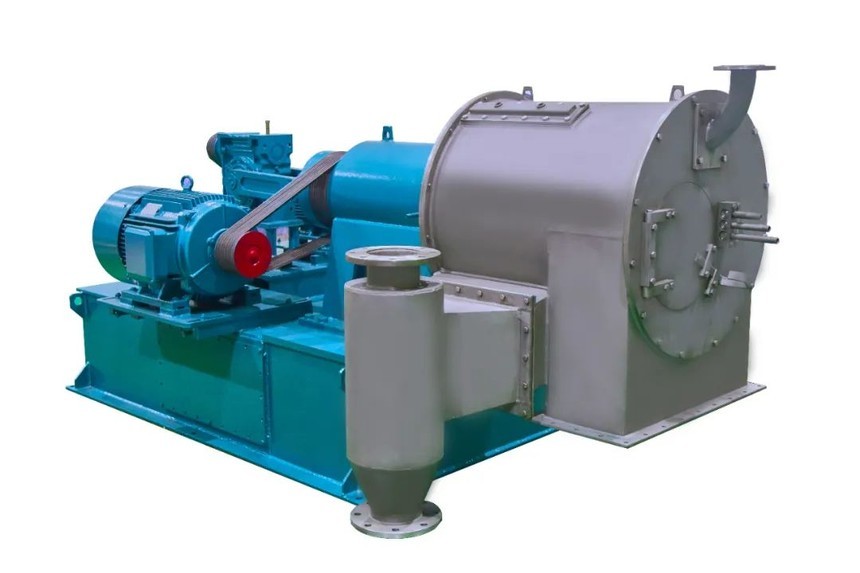

Summary: Recently, Chongqing Jiangbei Machinery Co., Ltd. successfully developed a new two-stage pusher centrifuge hrj energy-saving piston pusher centrifuge. This centrifuge adopts a pure mechanical pusher drive structure design, which has better transmission efficiency and energy saving performance than the traditional hydraulic pusher centrifuge, providing a new choice for users to create economic and social benefits.

Recently, JBMACH successfully developed type HRJ pusher centrifuge which adopts a pure mechanical pusher drive structure design, which has better transmission efficiency and energy saving performance than the traditional hydraulic pusher centrifuge, providing a new choice for users to create economic and social benefits.

Structure and principle

The centrifuge is mainly composed of frame, casing, bearing assembly, drum, screen, reducer and other components.

The pushing mechanism is composed of a motor, a reducer and an eccentric shaft. The crank slider mechanism converts the rotating motion of the motor into a reciprocating pushing motion. The revolving body is connected with the belt pulley of the main motor through a triangular belt. The mechanical pushing mechanism has applied for a national patent and obtained authorization.

When the main machine is running at full speed, the suspension enters the drum through the feed pipe. Under the action of centrifugal force field, the suspension is evenly distributed on the drum screen. The liquid phase is discharged through the screen gap and the drum filter hole, while the solid phase is intercepted on the screen surface to form an annular filter cake layer. Through the reciprocating motion of the inner drum, the filter cake moves forward along the axial direction of the drum and is discharged through the aggregate tank in front of the outer drum.

Features and advantages

▲ HRJ energy saving piston pushing centrifuge

Compared with the traditional hydraulic structure, it has high transmission efficiency, low energy consumption and more energy saving. For HR500 model, the hydraulic drive type empty car current is about 20a, the mechanical pushing structure current is about 10a, and the power consumption is reduced by 50%.

The traditional hydraulic drive mechanism is canceled, and cooling water is not required, so the site is cleaner and environment-friendly.

Simple structure, easy maintenance and lower maintenance cost.

The machine runs at a constant full speed to complete the operation procedures such as feeding, separation, washing, drying and unloading, and the machine runs more smoothly.

All parts in contact with materials are made of stainless steel, so they have good corrosion resistance.

Applicable materials

Sodium chloride, sodium sulfate, sodium dichromate, ammonium sulfate, boric acid, cellulose acetate, nitrocellulose, ammonium chloride, caustic soda, potassium chloride, potassium sulfate, potassium carbonate, phosphate and other materials with particle size of 0.1~3mm.

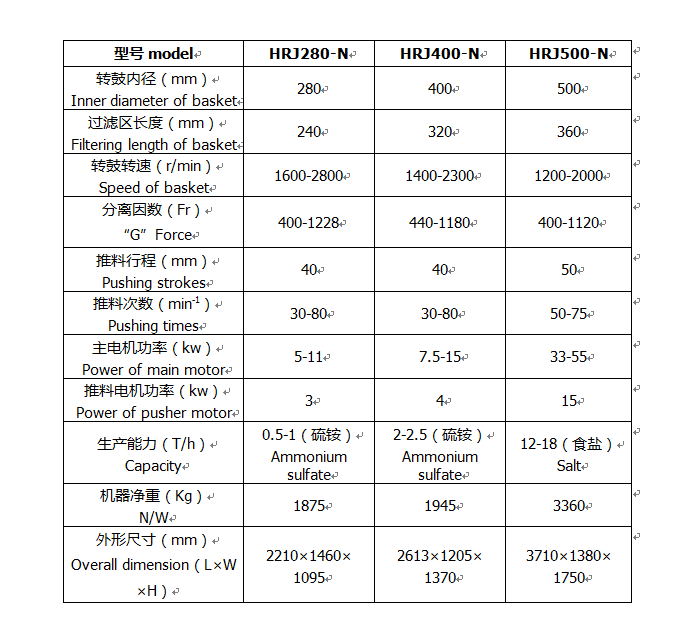

Main technical parameters

Keywords: New product | JBMACH Launohs Type HRJ Pwsher Centrifuge

Related News

knowledge

-

Understanding the Advantages of Mechanical Pusher Centrifuges in Industrial Applications

Time:2025-09-18

-

Understanding Peeler Centrifuges: A Key Component in Industrial Separation Technology

Time:2025-09-17

-

Exploring the Innovative Uses of Screen Scroll Centrifuges in Food Processing

Time:2025-09-16

-

Newest Screen Scroll Centrifuge from China Manufacturer Enhances Separation Efficiency

Time:2025-09-16

JBMACH News

-

The 19th Shanghai International Starch and Starch Derivatives Exhibition ended successfully | Jiangbei Machinery is with you all the way

Time:2025-07-22

-

Precise diagnosis and meticulous maintenance: Chongqing Jiangbei Machinery helps customers revive imported brand centrifuges

Time:2025-07-22

-

Resources aggregation, discussing the future

Time:2025-07-22

-

Good News | Warmly Congratulate Chongqing Jiangbeimach Won A Series of Honors and Certificates Including the Certification for Five-Star Commodity After-sales Services!

Time:2023-08-24

-

Chongqing Jiangbeimach Makes a Wonderful Appearance at the 11th China International Fluid Machinery Exhibition

Time:2023-03-08

-

Chongqing Jiangbeimach Co., Ltd. special training class for marketing and service successfully completed!

Time:2023-01-28

-

Chongqing Jiangbeimach Co,. Ltd. won the "Leap-forward Development Award" of CQME

Time:2023-01-15

-

The fourth Technical Exchange Forum of Chongqing Jiangbeimach Co,. Ltd. in 2022 was successfully held

Time:2022-12-29

-

JBMACH peeler centrifuge operation and maintenance special customer training meeting was successfully concluded

Time:2020-09-14

-

JBMACH launchs its type LWM-NG centrifuge for α gypsum decantering at a operating temperature of 120°C

Time:2021-07-23

-

New product | JBMACH Launohs Type HRJ Pwsher Centrifuge

Time:2021-07-23

-

The first National Youth Forum on advanced separation technology was held in Shanghai | co-organized by JBMACH

Time:2019-12-03

-

Our employees won excellent results in the first skills competition of Liangjiang New Area

Time:2021-11-26

Industry News

-

Assisting the development of new energy - JBMACH was elected as the deputy director unit of Cisia's Technical Committee for LiFP

Time:2021-07-28

-

Good news and good achievements | JBMACH won many industry awards

Time:2021-07-26

-

The 10th China (Shanghai) International Fluid Machinery Exhibition came to a successful conclusion | JBMACH is grateful to have you along the way!

Time:2020-12-02

-

The 15th Shanghai International Starch and starch derivatives exhibition is about to open! JBMACH meets you in Shanghai!

Time:2020-11-25